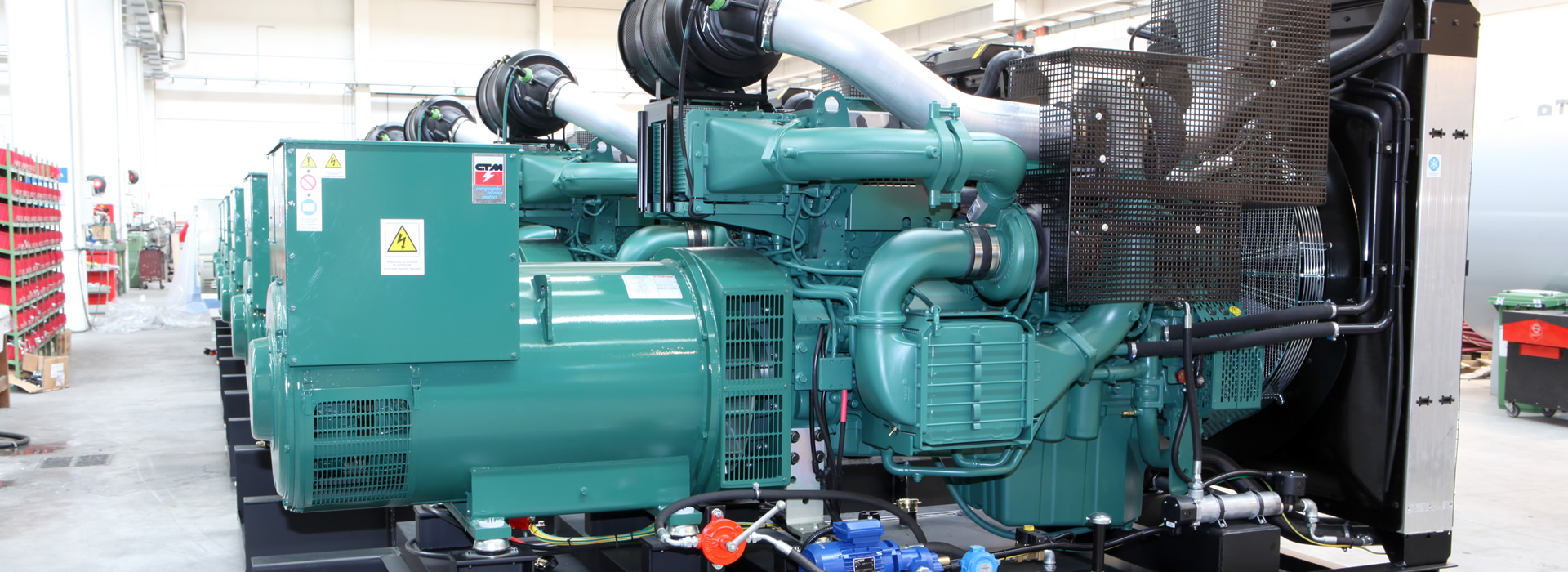

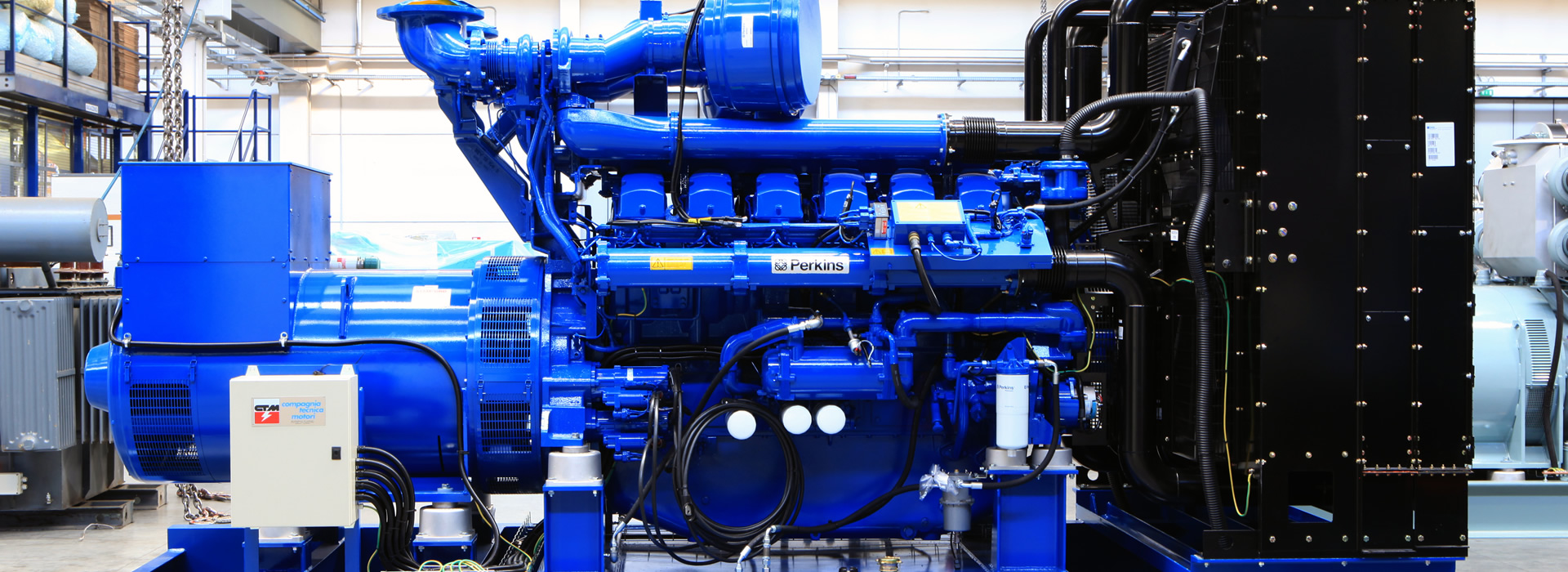

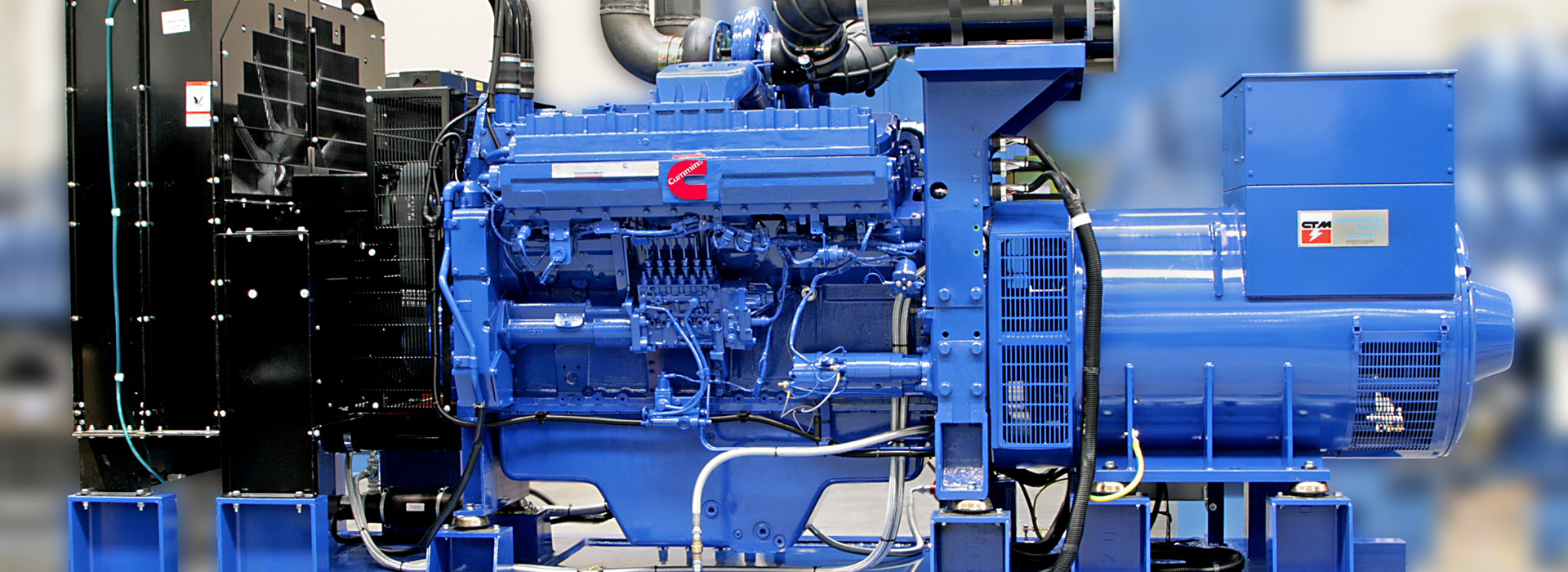

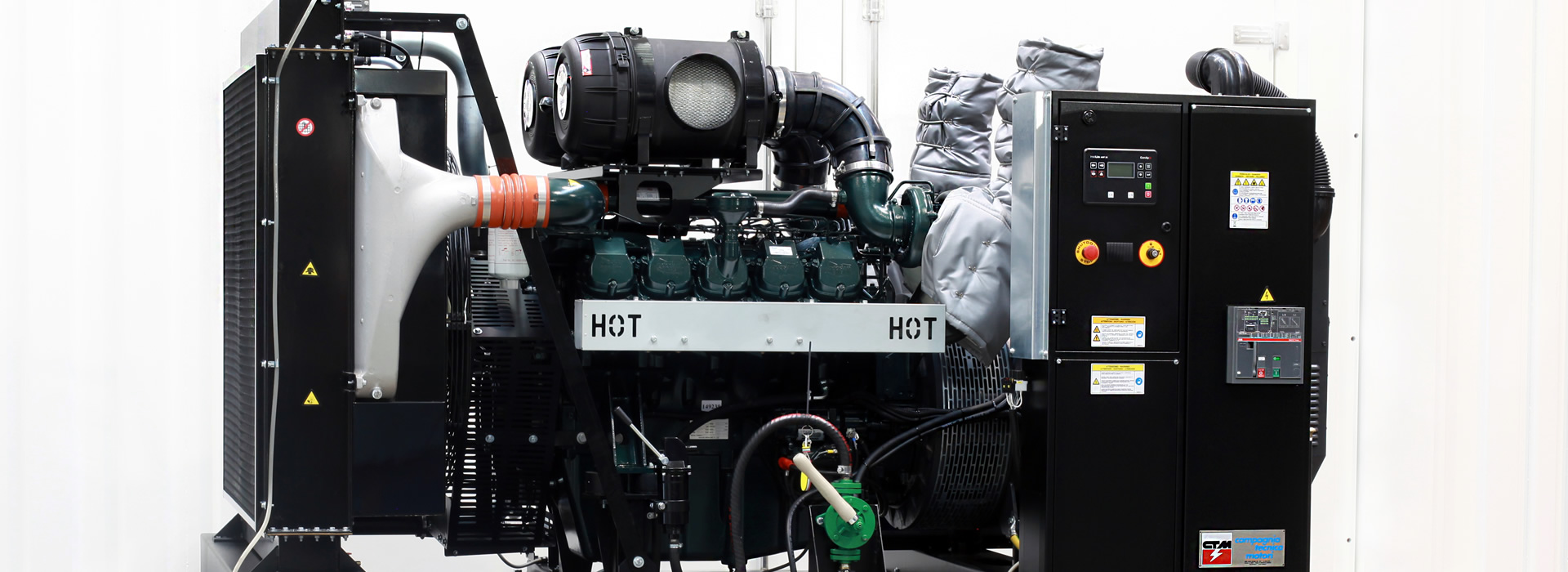

Standard Diesel and gas generators

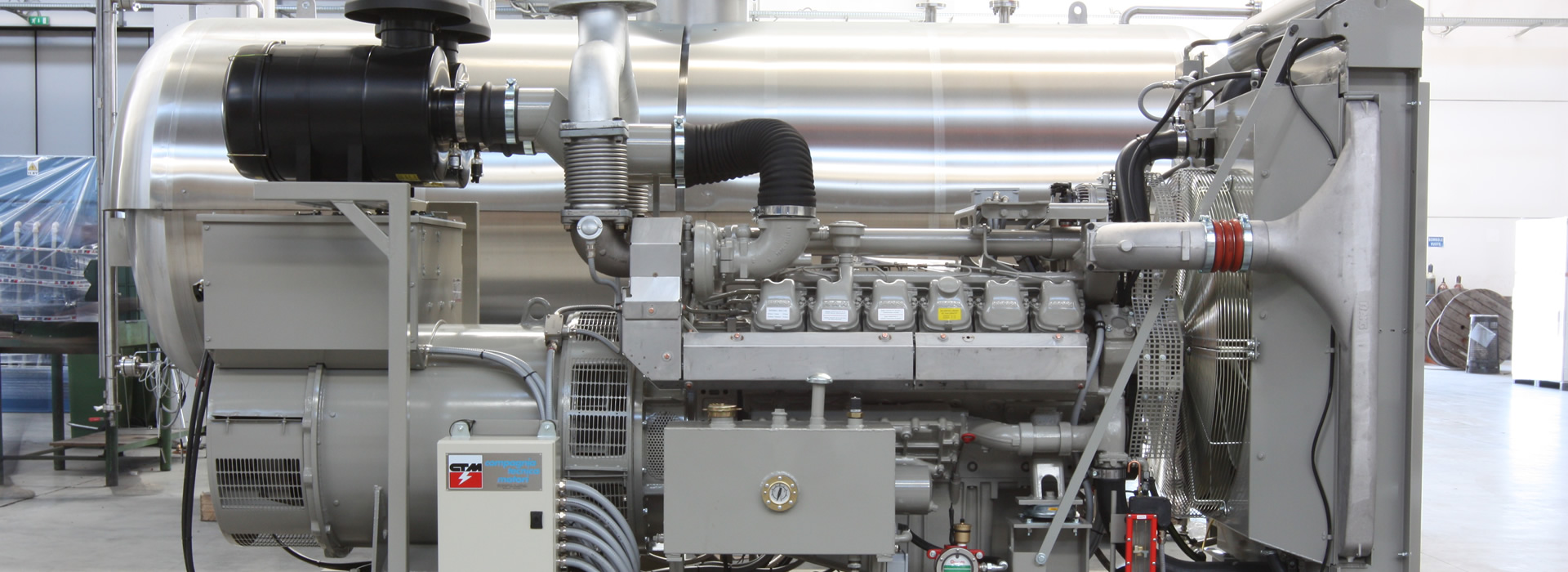

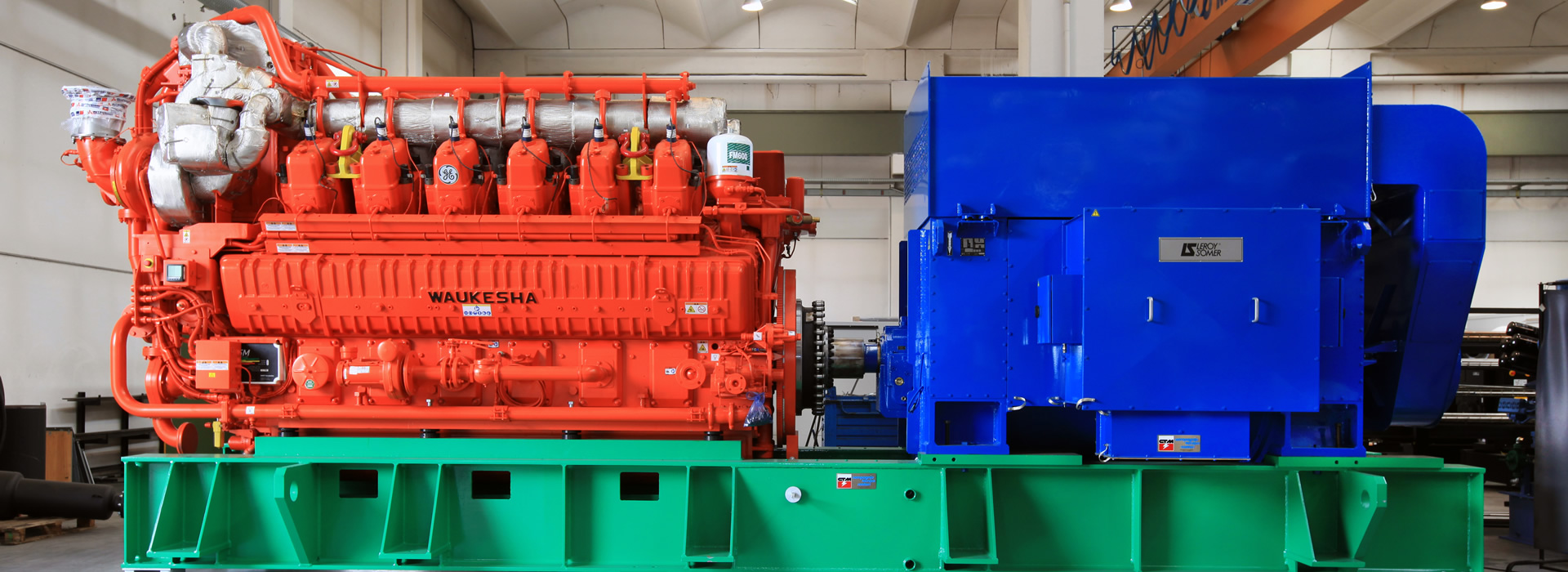

Compagnia Tecnica Motori can offer a wide range of standard diesel and gas generators relaying on the most important engines and alternators international manufacturers.

Our Generators are the perfect solution wherever power has to be generated quickly, reliably and efficiently.

Our Generators are designed, manufactured according to ISO 9001 quality management system, ISO 14001 environmental management system and ISO 45001 health and safety management system

Applicable Standards and Code

General Directives |

Standards – Generating set |

|

|

Standards - Engine |

Standards - Alternator |

|

|

Standards – Electrical equipment |

Standards – Fuel tank Welding Painting

|

Standard Specifications

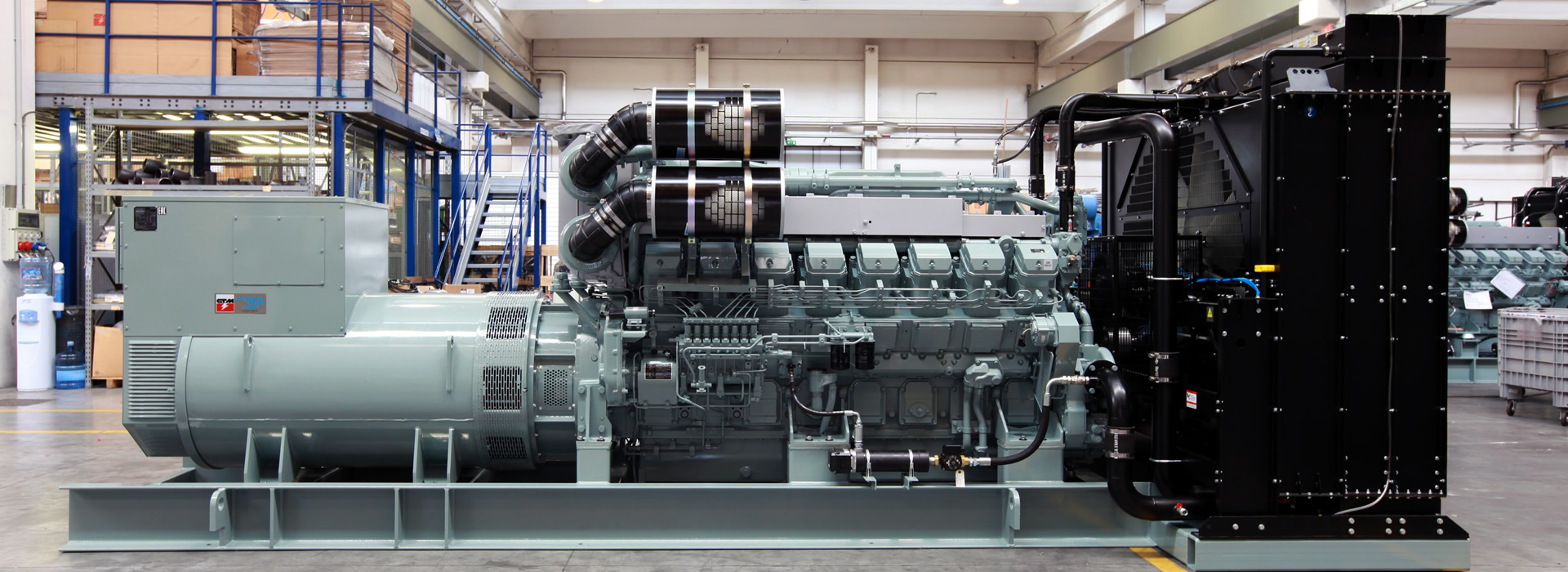

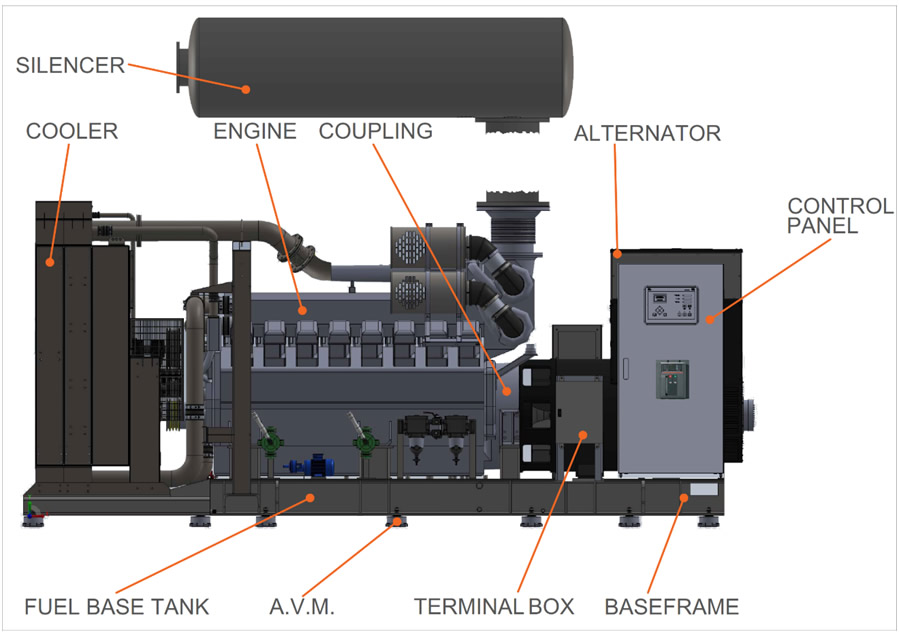

Engine

Reciprocating internal combustion diesel engines multi-cylinders in-line or “V” disposal, naturally aspirated or turbocharged, intercooled with mechanical governor or electronic upon request, or “common rail” type. Engines are equipped with air filters with replaceable elements with restrictor indicators.All rotating machinery and hot elements are equipped with safety guards. Engines are complete with electric starting systems with starting motor, alternator battery charger and lead acid batteries 12 V or 24 V.

Engines can also be fuelled by HPO according to EN 590.

Alternator

Alternators are synchronous, three phases, static excitation, brushless, self-regulated and self-ventilated, with IC-01 IC-0A1 system in compliance with IEC 34, VDE 0530, DIN-EN 60034 directives, suitable for 50 Hz or 60 Hz, IP23 protection degree or different upon request. The standard mounting is a single bearing configuration, and, on demand, double bearing is available. All alternators are equipped by automatic voltage regulator electronic type and, upon request, by permanent magnet and other accessories. Insulation is actually in class H, on demand, F or B.Coupling

Engines and alternators are connected together through a flexible disc coupling in case of single bearing alternators and rubber coupling for double bearings design.Cooler

The cooling of the engine is undertaken by the radiator with a pusher fan, mechanically engine driven by belts or by electric motor fans; alternatively separate cooling systems with a top tank and level indicators can be provided (upon request). The cooling system comprises a preheating system with thermostatic control and circulating pump.Baseframe

Metallic base frames made welded steel sections. All base frames are equipped with lifting points.The baseframes can be complete with integral fuel tank which can be of variable capacity to meet the customer's requirements and applicable regulations, drip pan as option.

AVM’s

AVM’s antivibration mountings are fitted between engine/alternator feet and baseframe or under the baseframe depending on models.Fuel base tank

The fuel base tank has a capacity for multiple hours requirements and is fitted with fuel fill cap, normal vent, fuel level gauge, flexible pipes to the engine, leak detection system within the drip tray and overflow connection.Terminal box

The wiring on board includes flame retardant cable in conduits and cable trays. All cables terminate into a set mounted terminal box.Control panel

The standard control panels are made of sheet steel structural work with IP44 minimum mechanical protection and 2B separation form – compliant with CEI – IEC – EN standards for electrical panels. The panels can be installed on board the unit or free standing and are normally complete with a GenSet protection breaker and controls for external switching.All panels are fitted with microprocessor advanced generating set control boards with PLC functions on request.

Silencer

The exhaust gas silencers, included in standard scope of supply, to limit noise, can be industrial, residential, critical and are supplied loose, complete with expansion joints and spark arrestor as option.